How to Maintain Expensive Farm Machinery for Long-Term Reliability

Farm machinery is the backbone of modern agriculture, helping farmers increase productivity and efficiency. However, we see a lot of expensive repairs that a little preventative maintenance could have stopped.

- Regular Inspections

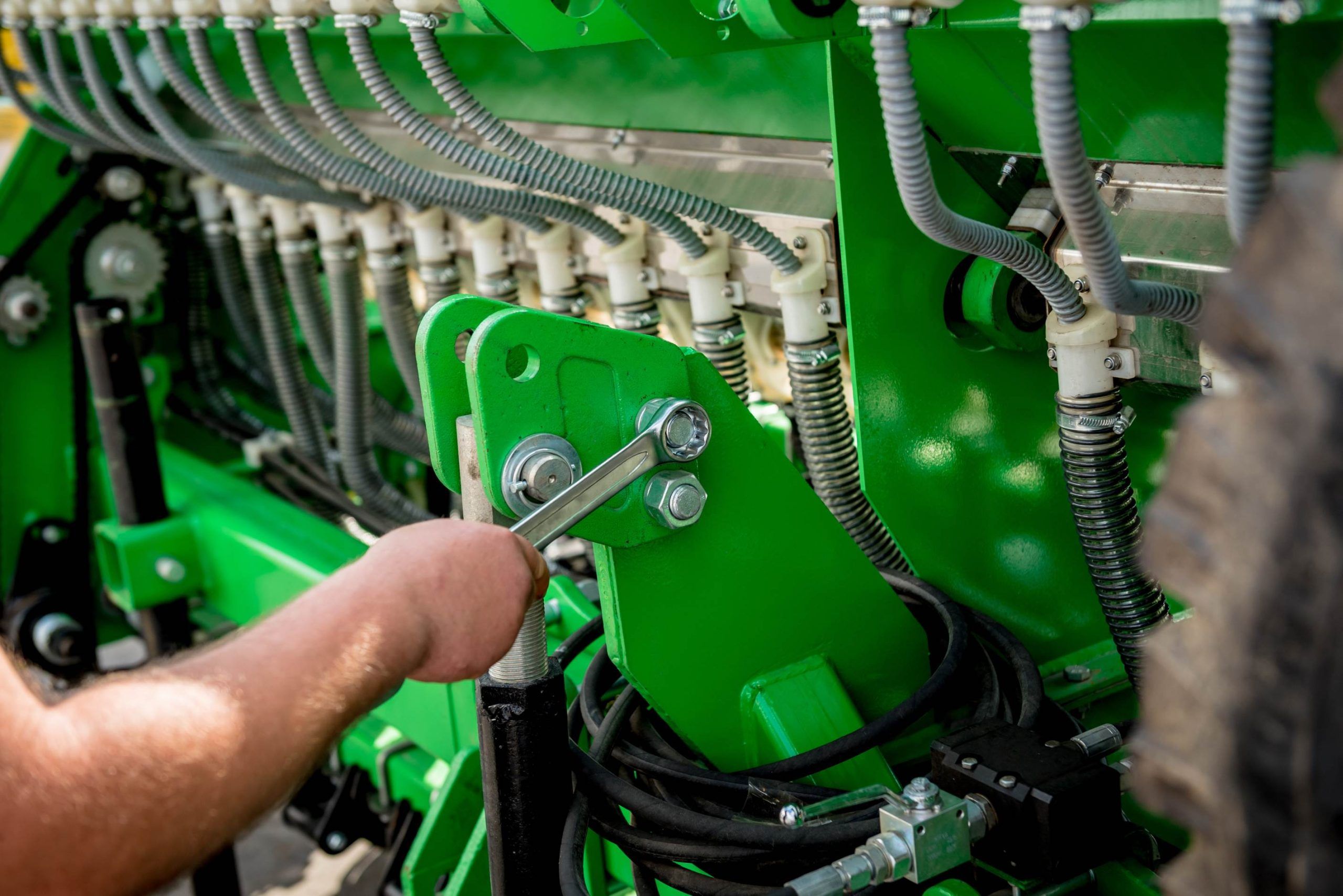

Regular inspections are the foundation of farm machinery maintenance. By frequently checking your equipment, you can identify issues early and prevent them from escalating into costly problems. Here are some key areas to inspect:

- Lubrication: Ensure that all moving parts are adequately lubricated to reduce friction and wear. Use the manufacturer’s guidelines for recommended lubrication intervals.

- Belts and Chains: Inspect belts and chains for signs of wear, tension, and proper alignment. Replace any damaged or worn-out components promptly.

- Fluids: Check engine oil, hydraulic fluid, coolant, and other fluids regularly. Maintain the correct levels and change them at the recommended intervals.

- Tires: Examine tire pressure and condition to ensure even wear and optimal traction. Under-inflated or damaged tires can lead to reduced fuel efficiency and increased wear on machinery.

2. Cleaning and Rust Prevention

Farm machinery is exposed to a variety of harsh environmental conditions, including dirt, dust, and moisture. Regularly clean your equipment to prevent the buildup of debris and rust. A clean machine not only looks better but also operates more efficiently and has a longer lifespan.

Pressure washing: Use a pressure washer to remove dirt and grime from your machinery. Pay close attention to areas where dirt tends to accumulate, such as around the engine and under the chassis.

*Tip from our experts* Wait until a machine has cooled down before washing; otherwise, the water can be sucked into the bearings as they cool.

Rust prevention: Apply rust-resistant coatings or paint to exposed metal surfaces. Inspect and touch up any areas where paint has chipped, or rust has formed.

3. Professional Maintenance

While regular inspections and basic maintenance can be done by farmers themselves, it’s crucial to engage professionals for more complex tasks. Consider scheduling routine maintenance with a qualified technician who is experienced with your specific machinery. They can diagnose and address issues that may not be apparent during regular inspections.

4. Store Equipment Properly

Proper storage is often overlooked but plays a significant role in the long-term reliability of farm machinery. Store your equipment in a dry, sheltered area to protect it from rain, snow, and direct sunlight. Cleaning and greasing all wearing parts and bearings before storage will keep moisture out. If possible, keep machinery indoors during the off-season. Storing equipment correctly can prevent rust, deterioration of rubber components, and electrical issues. There’s nothing worse than pulling a machine out of the shed and finding it doesn’t work.

5. Training and Documentation

Invest in training for your farm equipment operators. Proper training ensures that machinery is operated correctly, reducing the risk of premature wear and damage due to operator error.

Keep detailed records of all maintenance activities, repairs, including dates, parts replaced, and any issues identified during inspections. This documentation can be invaluable for tracking equipment history and making informed decisions about repairs and replacements.

Farm machinery is a substantial investment for any agricultural operation and maintaining it for long-term reliability is crucial. Regular inspections, cleaning, rust prevention, record-keeping, and professional maintenance are all essential components of a successful machinery maintenance program. Call Mech Agriculture on 06 356 8781 for booking a pre-season service.

By prioritizing maintenance, farmers can not only extend the lifespan of their equipment but also increase overall farm productivity and reduce long-term operating costs. Remember, a well-maintained machine is a reliable and efficient one.